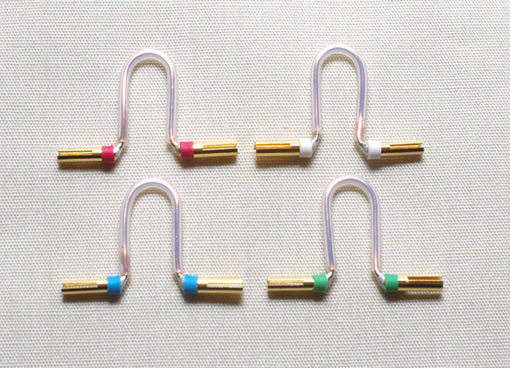

6N copper anneal single Wire Shell lead YR-03 6,000yen (1 set)

Shell lead YR-03 is a lead it is a high quality lead for head shell which uses purity 6N copper anneal single wire.

Annealing treatment also calls it annealing (burning and carrying out raw) processing, and it heats copper wire to the temperature of about 450 degrees at a vacuum furnace.

The thing of processing in which it cools gradually is said.

When lengthening a copper material to a line, it lengthens on a thin line gradually from a thick line by a machine called a dice.

In that case, in response to the power in which a copper material is big, a molecule receives stress, and the finished line becomes hard.

It is annealing treatment to remove the stress of the line by annealing treatment, and to return the row of a molecule to the state where there is no stress.

It is said that the row of a molecule becomes equal, a material becomes soft, electrical resistance falls, and the electric conduction rate of a copper material improves by annealing treatment.

When it is used for audios, though it is a generally firm sound, it becomes the tendency to also make a soft sound.

From that of the copper generally marketed, since a line is made from continuation processing, annealing treatment etc. is impossible,

Considering the diameter of an electric wire, it becomes a harder line and it is thought that it is inferior to the wire rod which carried out annealing treatment also in respect of a characteristic top or sound quality.

In YR-03, the single track of the diameter of 0.6mm of the 6N copper wire which carried out annealing treatment is used.

The insulation material is using the Teflon which was most excellent in the electrical property in the state of a tube.

I have adopted as the terminal part of YR-03 YRT-01 and the equivalent article which have been put on the market alone at us.

At us, many tube sockets are manufactured for some time, and those product development technology is applied,

I am manufacturing the connector terminal which it began to delete from the round bar of phosphorus bronze excellent in the product made from a spring.

As for a shell lead terminal, the arm side is finished very as minute the diameter 1.0mmphi and cartridge side as 1.2mmphi,

By sound quality serious consideration, the nonmagnetic ground was given and also I have plated the pole thickness of 1.0 microns with gold.

Connection of a terminal and a lead has adopted more positive soldering in YR-02, although sticking by pressure is generally adopted.

Careful selection use of the high-quality sound unleaded type solder is carried out at solder.

When a poor thing is used for a shell lead, it becomes the poor sound for which a feeling of energy was insufficient.

For single track, the material currently used for YR-03 will serve as a tendency of the sound which became tight compared with the line more, and will pull out a forcible sound from the cartridge in use.

The terminal of a shell lead be suitable in parallel with the terminal of a cartridge before connection when using it.

I recommend you to bend a lead portion beforehand.

Please take care, especially when you make a line cross and you wire like the cartridge of DENON.

Although this line is soft, since it is single wire a repetition bending, please keep in mind that it may lead to breakage of a line.

YR-03 Standard

Kind: -- shell lead 4 color set (with a terminal) a length about 1.8cm U type --

Kind of forming finishing wire rod: -- 6N copper anneal single track 0.6 dia. (cross-section area about 0.28 squares)

Charge of insulation material: -- quality-of-the-material of a PTFE tube terminal bronze and 1micro of gilding with a nonmagnetic ground

Price: 6,000 yen (one set and the main part price classified by tax)